¿Por qué los hornos de descarbonización continua están reemplazando a los decapantes químicos de pintura?

Oct 18, 2022

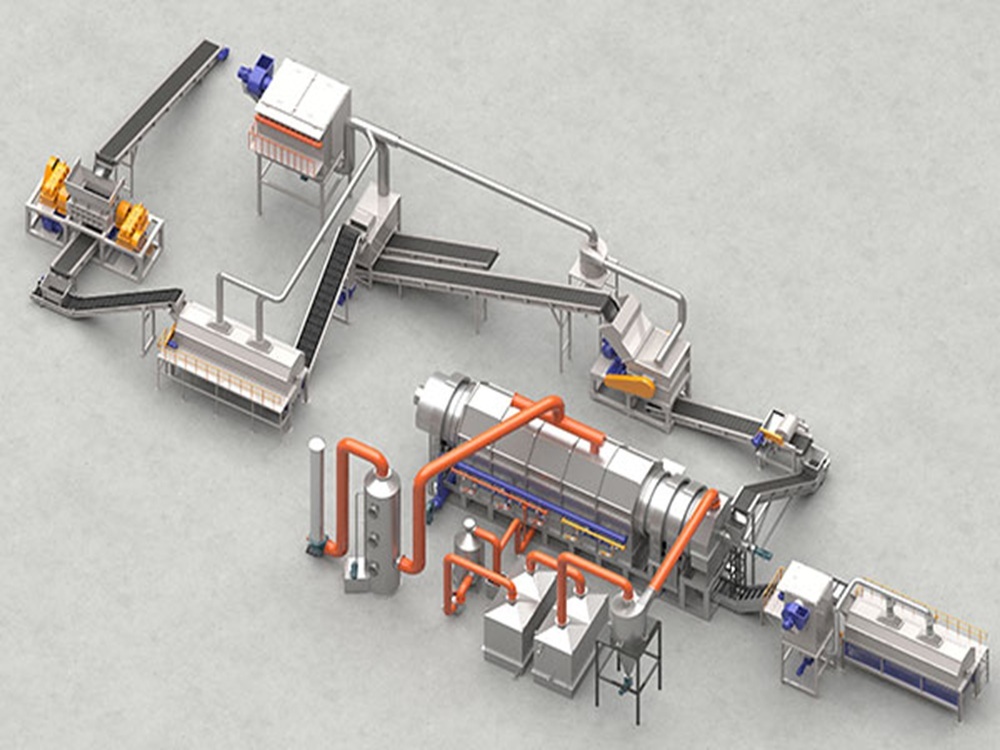

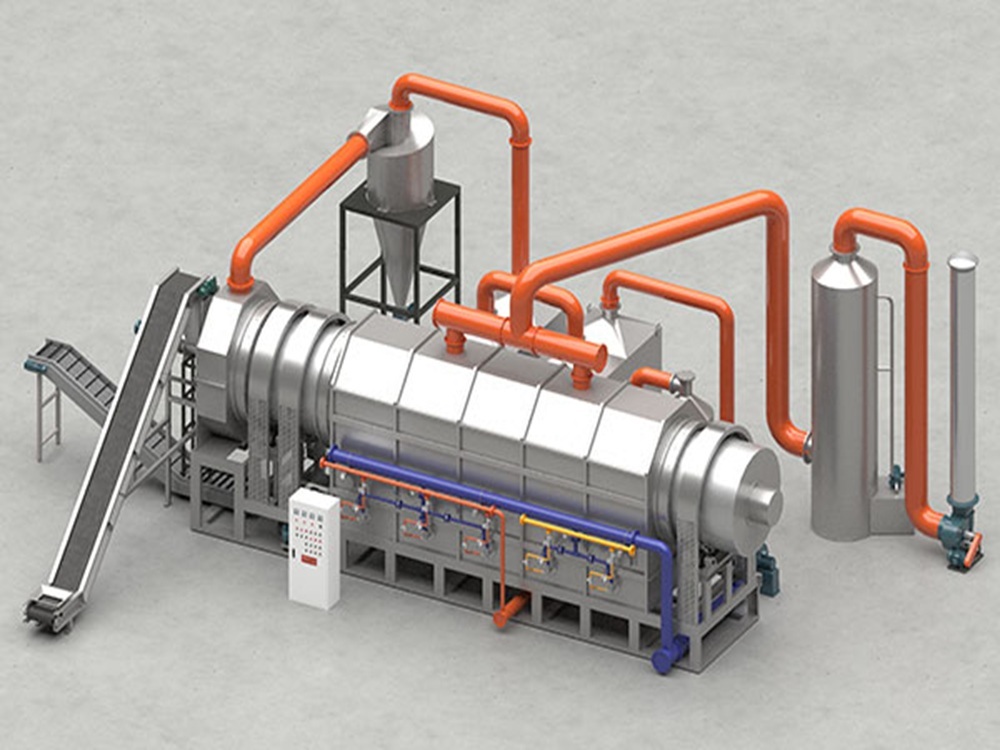

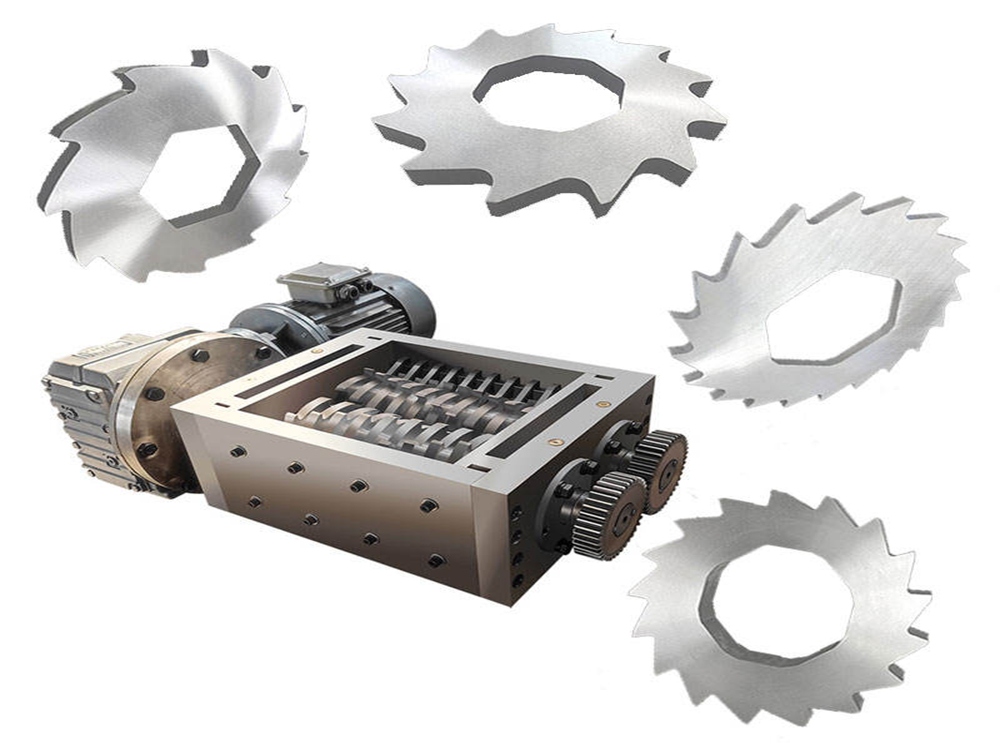

En el reciclaje y reacondicionamiento de metales, la eliminación de pintura y recubrimientos de las superficies es un paso crucial. Durante décadas, los decapantes químicos fueron la solución preferida. Sin embargo, hoy en día, los hornos de decapado continuo se están convirtiendo rápidamente en la opción preferida, ofreciendo una combinación superior de eficiencia, seguridad y sostenibilidad. Entonces, ¿qué hace que esta tecnología sea tan superior? A continuación, presentamos un resumen de sus principales ventajas respecto a los métodos químicos tradicionales. 1. Eficiencia inigualable y funcionamiento continuo Imagine una línea de montaje para limpiar metal. Eso es básicamente lo que hace un horno de desrecubrimiento continuo A diferencia de los procesos por lotes, funciona sin interrupción, alimentando piezas metálicas a través de diferentes zonas para calentarlas, procesarlas y enfriarlas. Este flujo de trabajo continuo se traduce en un rendimiento considerablemente mayor. Independientemente de si los artículos tienen capas de pintura finas o gruesas, los parámetros del horno, como la temperatura y la velocidad de procesamiento, se pueden ajustar fácilmente para lograr una tira perfecta y limpia. Esta flexibilidad lo hace ideal para manipular eficientemente una amplia variedad de piezas metálicas, ahorrando tiempo y mano de obra de forma significativa. 2. Una clara victoria para la seguridad y el medio ambiente Esta es quizás la ventaja más significativa. Los decapantes químicos suelen contener sustancias tóxicas y agresivas que representan riesgos para la salud de los trabajadores y el medio ambiente. Su manipulación segura requiere estrictas medidas de protección, y la eliminación de los productos químicos usados genera residuos peligrosos. El horno de decapado elimina este problema por completo. Utiliza altas temperaturas en un entorno controlado y sin oxígeno para descomponer la pintura en gas y una pequeña cantidad de residuos sólidos. Es un proceso puramente físico: no se necesitan productos químicos tóxicos. Esto significa que no hay humos peligrosos para los trabajadores, ni riesgo de derrames químicos, ni aguas residuales tóxicas que tratar. Es una solución mucho más limpia y segura para todos. 3. Operación sencilla y fácil mantenimiento La gestión de decapantes químicos es compleja. Requiere procedimientos minuciosos de supervisión, almacenamiento y manipulación para evitar accidentes. En cambio, los hornos de decapado continuo están diseñados para simplificar el proceso. Las unidades modernas están equipadas con sistemas de control automatizados que gestionan todo el proceso: la temperatura, la velocidad del transportador y la atmósfera se controlan con precisión desde un panel. Esta automatización reduce la posibilidad de errores humanos y minimiza la necesidad de intervención de operadores especializados. El mantenimiento también es sencillo y suele incluir inspecciones periódicas y servicio básico para garantizar un rendimiento fiable a largo plazo. 4. Maneja casi cualquier pieza metálica La versatilidad es una de sus principales ventajas. Estos hornos se pueden adaptar para procesar piezas metálicas de diversas formas y tamaños, desde pequeños componentes hasta grandes piezas estructurales. Mediante el ajuste preciso de la configuración del equipo, se pueden tratar eficazmente diferentes materiales y tipos de recubrimiento. Esta amplia adaptabilidad hace que la tecnología sea útil en diversas industrias, como la fabricación de automóviles, la aeroespacial, el reciclaje de metales y la metalurgia en general. 5. Eficiencia energética y rentabilidad Si bien calentar un horno requiere energía, los diseños continuos modernos se construyen para lograr una mayor eficiencia. Los sistemas avanzados de aislamiento y recuperación de calor capturan y reutilizan el calor dentro del horno, lo que reduce significativamente el consumo de energía. Además, los gases combustibles producidos durante el proceso de decapado a menudo se pueden capturar y utilizar para alimentar el sistema, creando un circuito de ahorro energético. Con el tiempo, estas eficiencias conducen a menores costos operativos en comparación con el gasto recurrente de compra y eliminación de decapantes químicos. El cambio de los decapantes químicos de pintura a hornos de desrecubrimiento continuo Representa un gran avance para la industria. Con su eficiencia superior, perfil de seguridad mejorado, beneficios ambientales y simplicidad operativa, estos hornos no son solo una alternativa, sino una clara mejora. Se alinean perfectamente con los objetivos de la fabricación moderna y sostenible, ayudando a las empresas a trabajar de forma más inteligente, segura y ecológica.

LEER MÁS