Professionally Manufacturer Aluminum Profile Decoating Equipment Decoating Furnace with Automatic Conveyor

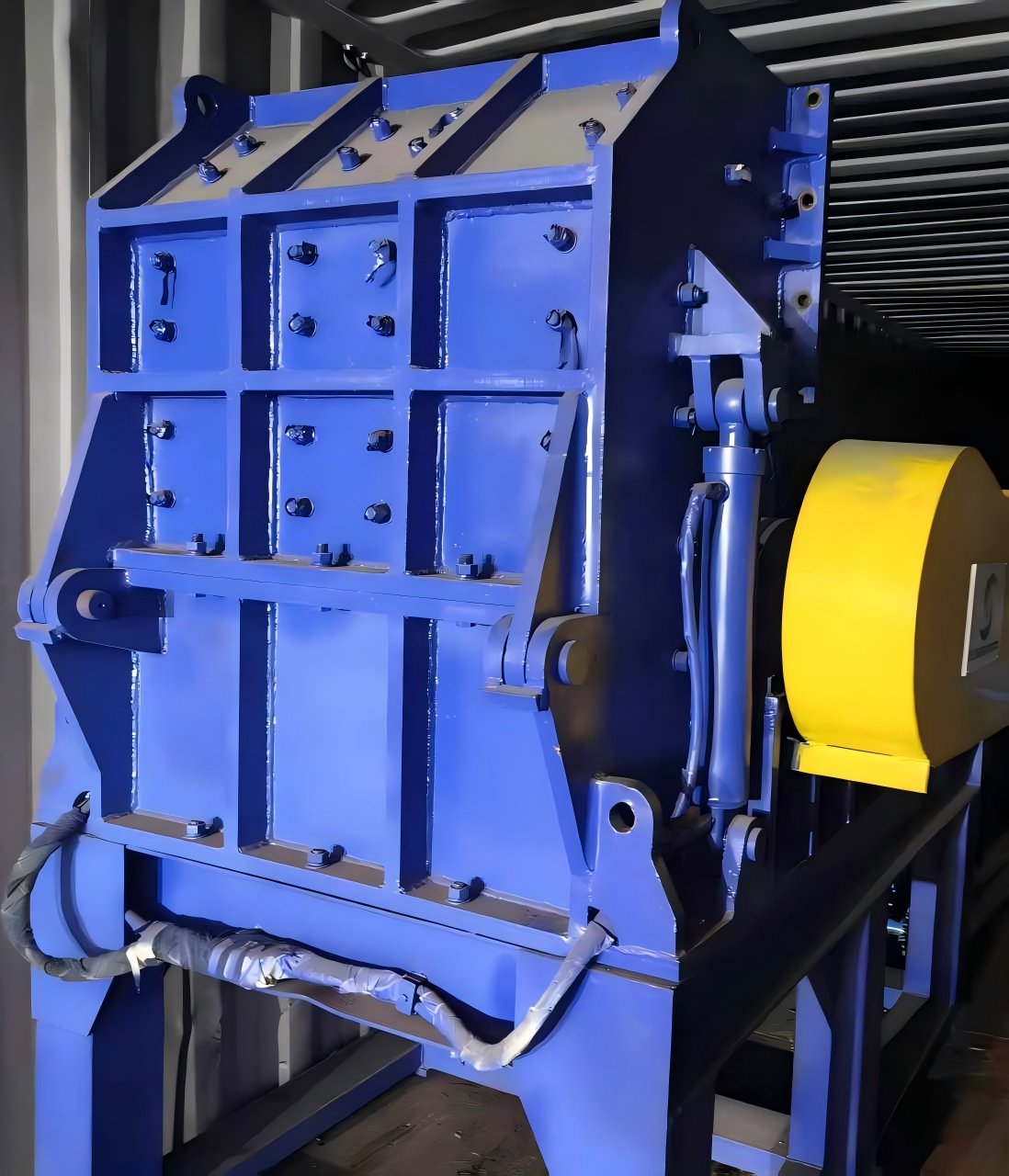

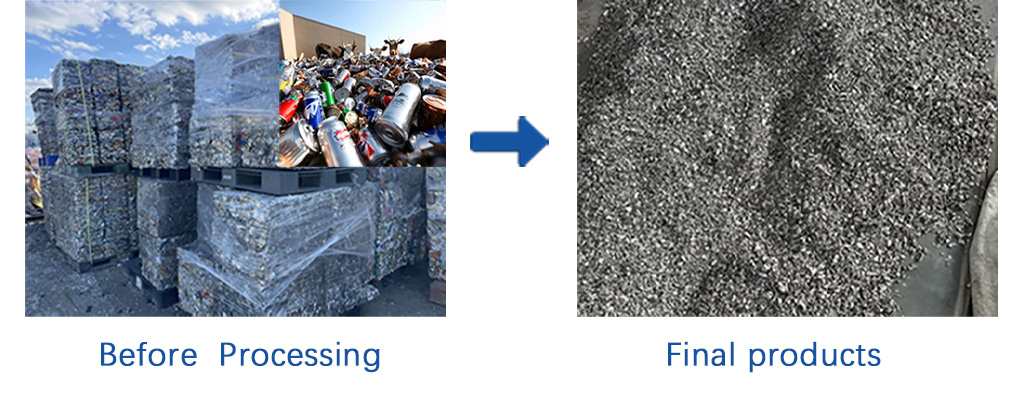

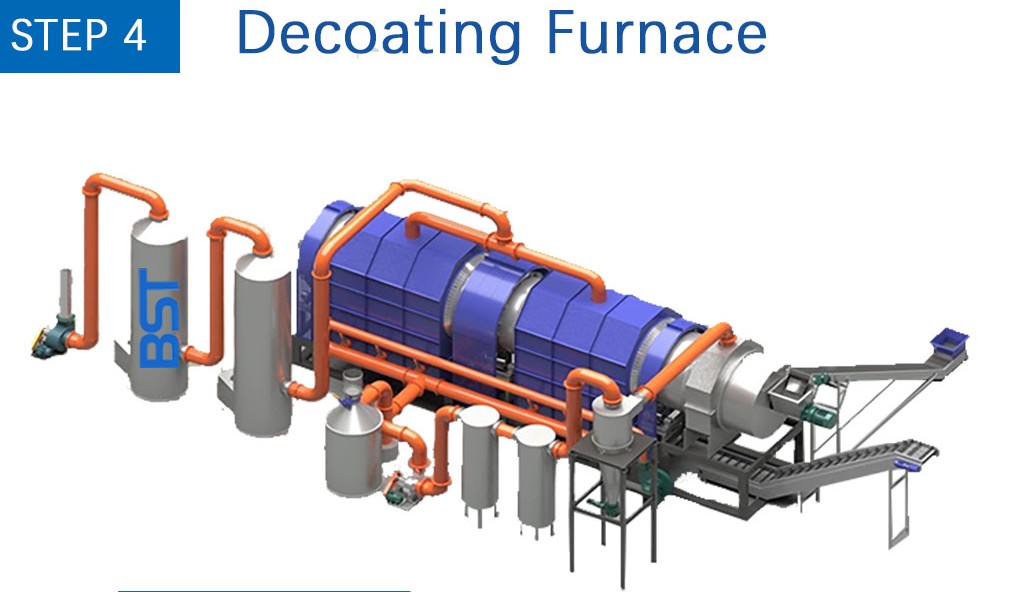

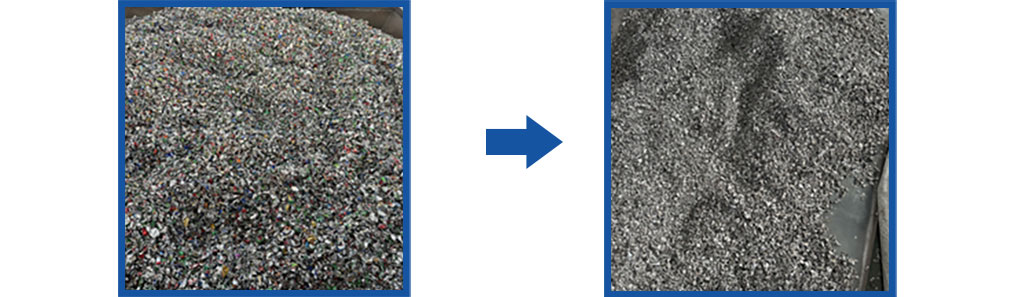

Engineered for relentless performance in scrap aluminum recycling, this furnace decoats shredded UBCs via aggressive yet precise heat cycles. Its rugged construction withstands thermal fatigue while proprietary burner technology selectively vaporizes coatings, leaving behind spotless aluminum fragments. Built-in redundancy systems ensure uninterrupted 24/7 operation, and real-time emission metrics sync with plant sustainability trackers—turning regulatory compliance into a competitive asset.

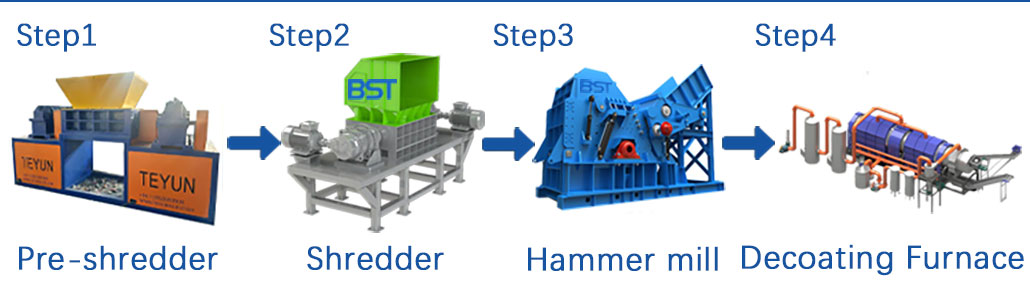

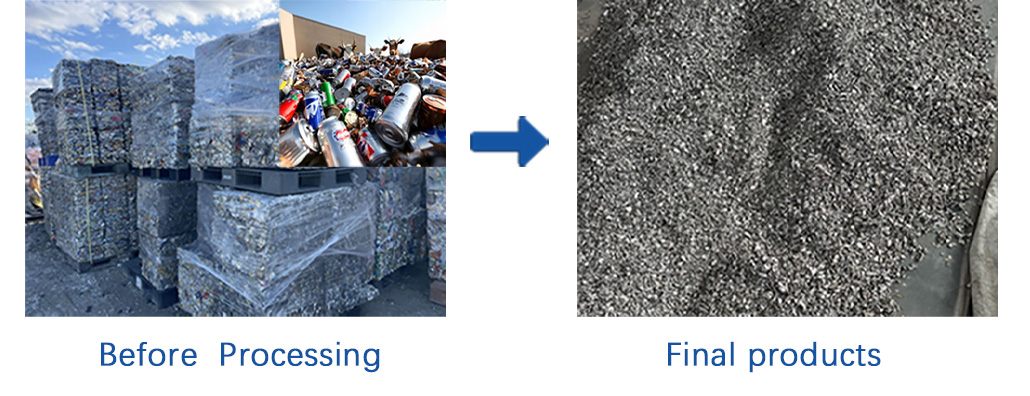

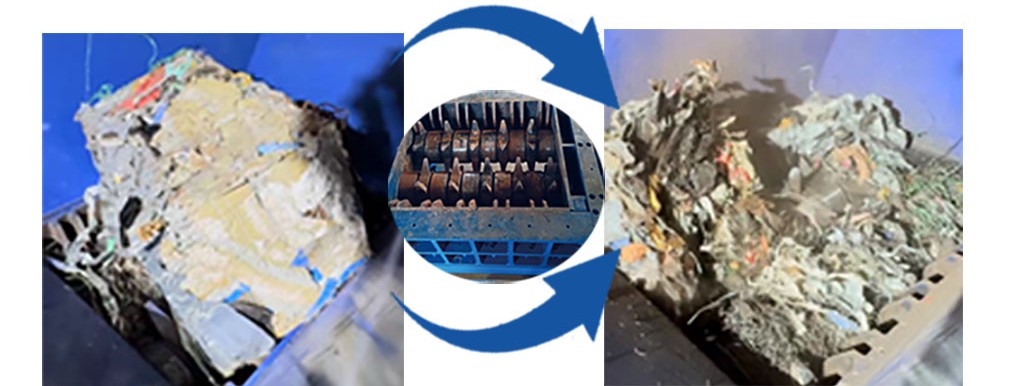

For the step one we use the Pre-shredder, to pre-deal with the bigger size metal scraps which are too big to put into the shredder and big size may broke the shredder. So the pre-shredder main function is to deal with the big size into the small size which suits for the shredder for next step.

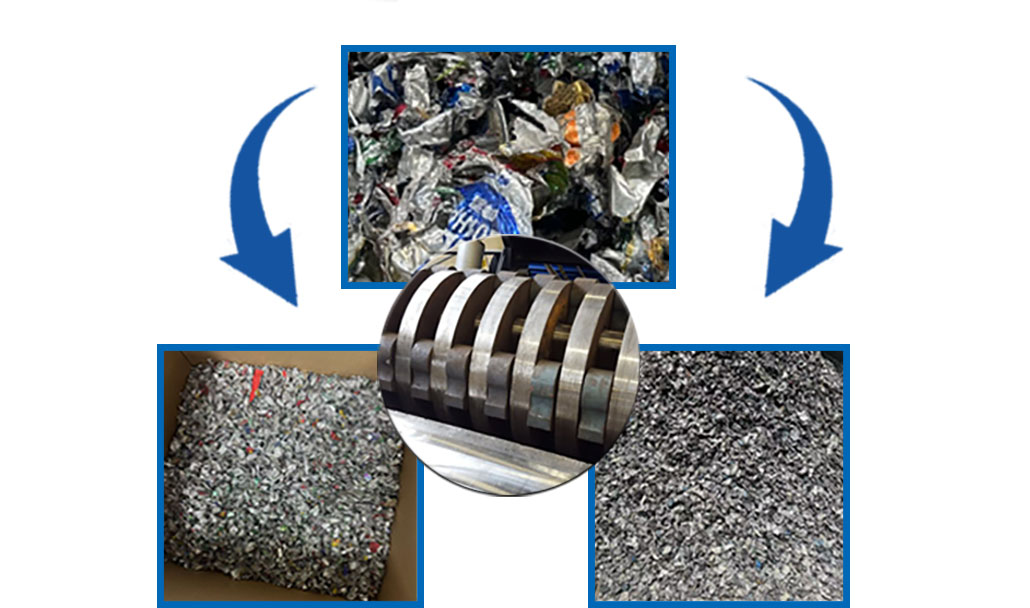

--------------占位---------------

It can be frequently reversed, Alloy casting, long service life. H13 shredder blade

High quality burners Second generation dust removal equipment Integrated electrical box

| Model | Best Feeding Temperature | Decoating Time | Processing Capacity (kg/h) |

| TY-1500 | 540℃ | 20-30min | 800 |

| TY-1800 | 540℃ | 20-30min | 1200 |

| TY-2200 | 540℃ | 20-30min | 1500 |

Español

Español English

English Français

Français Русский

Русский Português

Português عربي

عربي 日语

日语