Newest Technology UBC Recycling Machine Dec-coating Furnace for Scrap Metal Recycling

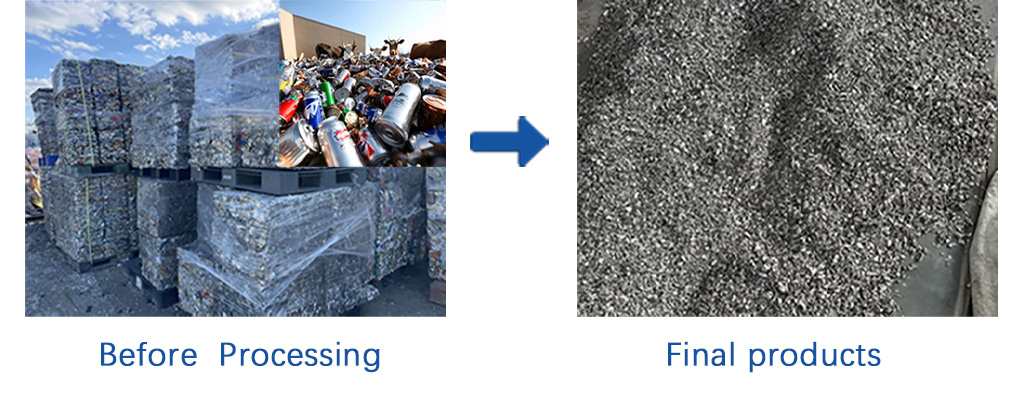

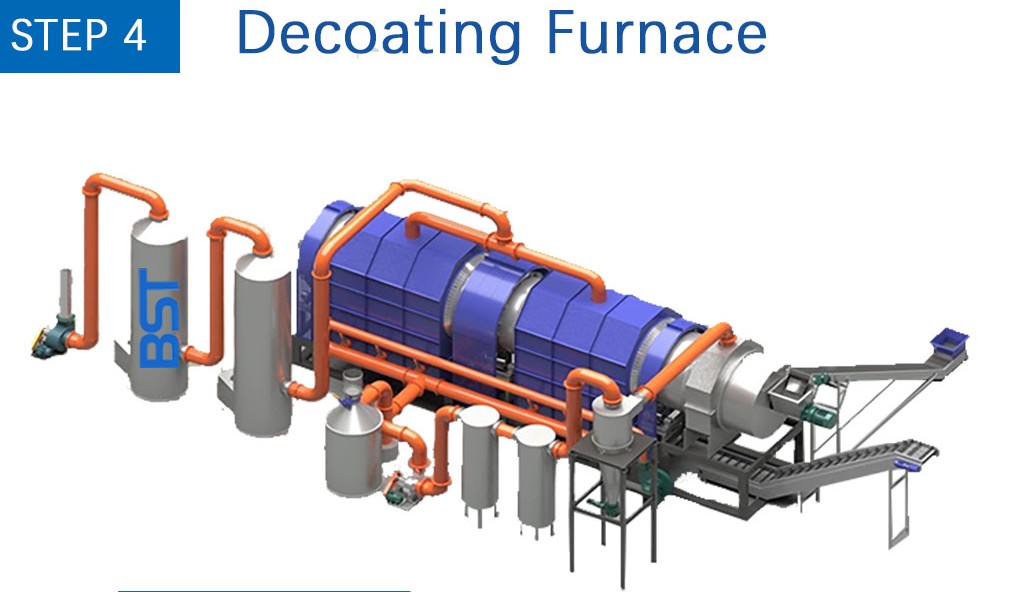

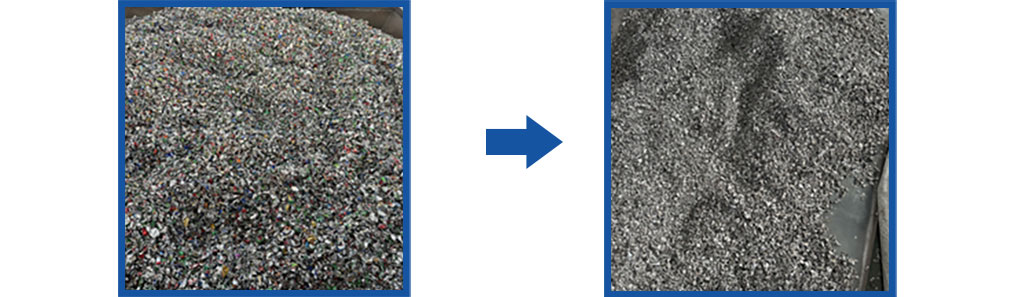

In order to make aluminum ingots or aluminum bars, raw aluminum is needed, some of which is primary aluminum and some is recycled aluminum. Usually, aluminum cans are an important way to recycle aluminum, but the surface of aluminum cans is painted, which requires a paint removing furnace. Therefore, the painting removing furnace(de-coating furnace) is an important equipment in the aluminum recycling production line.

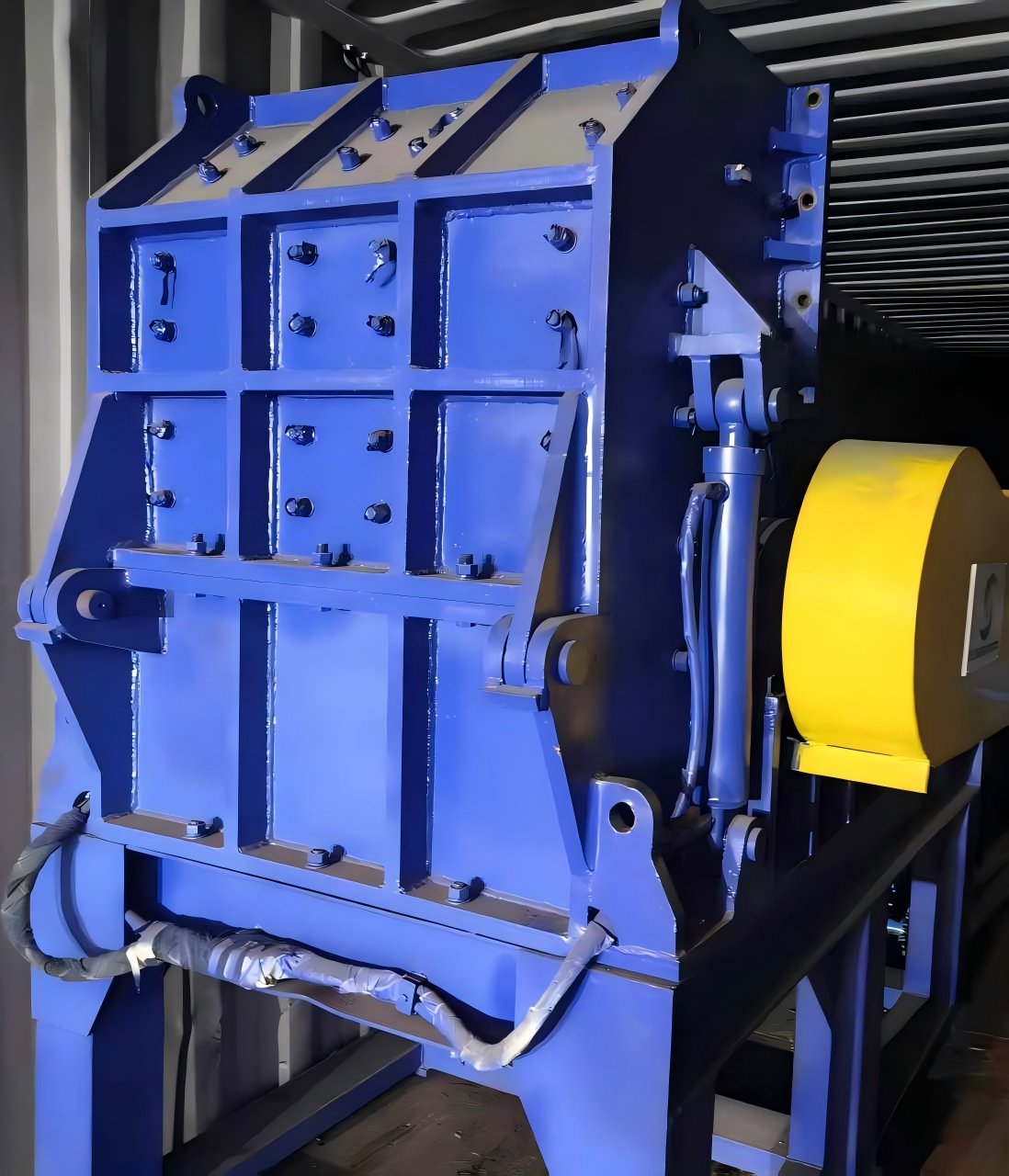

The de-coating furnace is a continuous and pyrolytic oven which can remove special or organic layers on the metal surface through closed high temperature (pyrolysis or chemical reaction) to meet environmental protection standards or recycling standards.

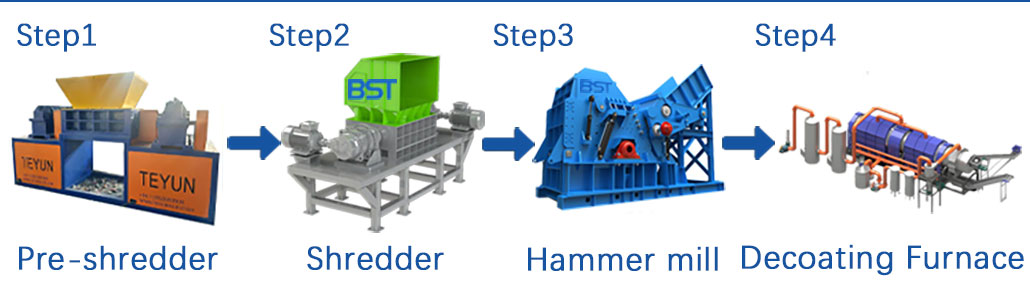

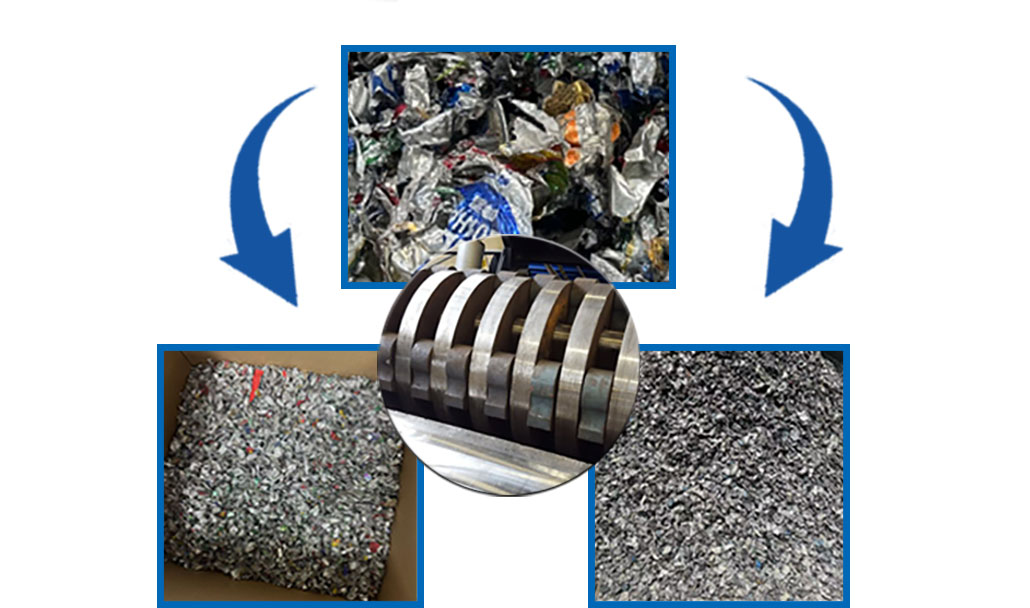

We can offer the whole line of the UBC aluminum cans recycling solutions not only for the painting removing.

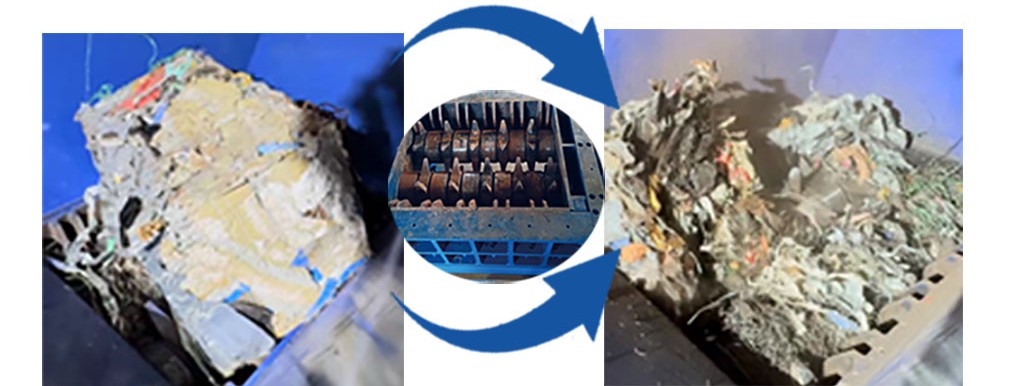

For the step one we use the Pre-shredder, to pre-deal with the bigger size metal scraps which are too big to put into the shredder and big size may broke the shredder. So the pre-shredder main function is to deal with the big size into the small size which suits for the shredder for next step.

Features of the de-coating furnace

1.Continuously feeding and out-put

2. Stably operation with high production

3.Painting removing rates can be over 99%

4.Equipped with dust removal device, can satisfy the environmentally friendly requirements

It can be frequently reversed, Alloy casting, long service life. H13 shredder blade

High quality burners Second generation dust removal equipment Integrated electrical box

| Model | Best Feeding Temperature | Decoating Time | Processing Capacity (kg/h) |

| TY-1500 | 540℃ | 20-30min | 800 |

| TY-1800 | 540℃ | 20-30min | 1200 |

| TY-2200 | 540℃ | 20-30min | 1500 |

Español

Español English

English Français

Français Русский

Русский Português

Português عربي

عربي 日语

日语