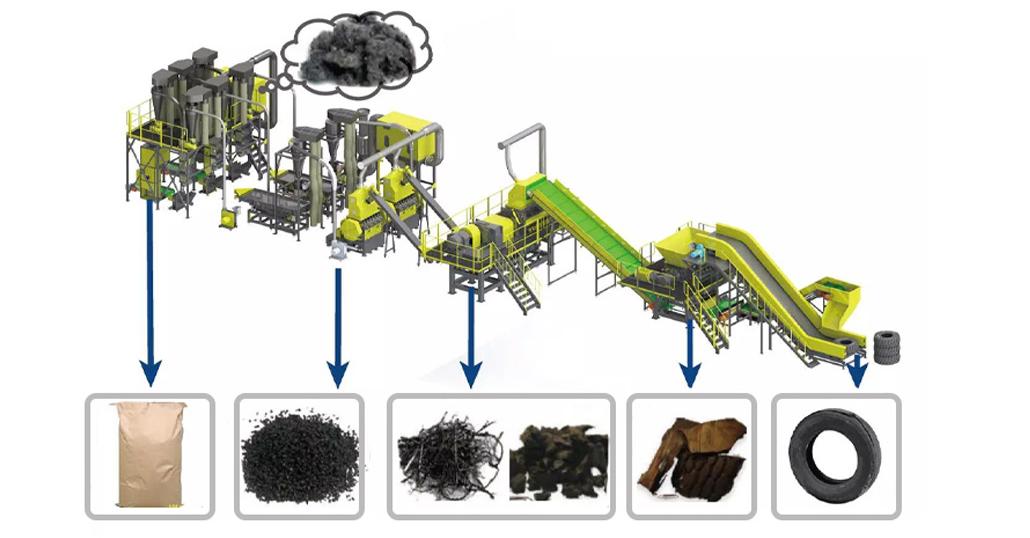

The tire recycling line is a production line used to process waste tires and realize tire resource utilization. It can realize the fully automatic separation of rubber, steel wire and fiber materials from car tires, truck tires, engineering vehicle tires and waste rubber products, and can pelletize and grind the rubber raw materials according to the actual needs of customers.

Working Process:

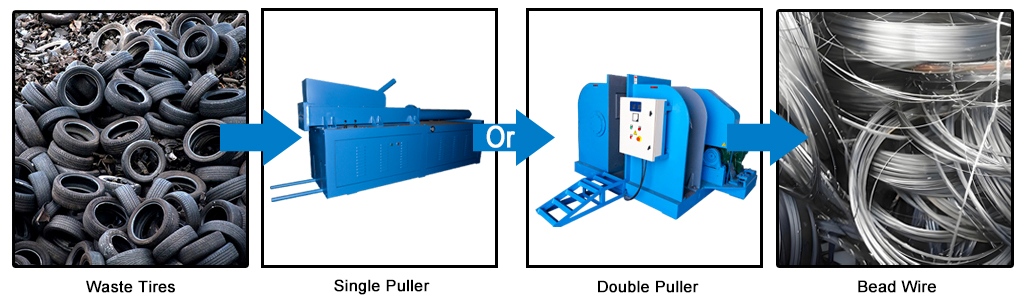

We have two types of bead wire pullers: single puller and double puller.

These machine completely extract inner bead wires in one operation to prepare tires for subsequent processing such as flattening or cutting.

Features:

1. It adopts an integrated bottom plate and is the most efficient wire pulling equipment on the market.

2. The double-pull wire pulling machine adopts a double-drive double-hook structure, which can pull out the wires on both sides of the tire at the same time, and its efficiency is 3 times that of a single-hook puller.

3. It is equipped with an automatic circuit protection system and a safety protection bracket.

| Single Puller | Double Puller | ||

| Model | BST-S-1200 | Model | BST-D-1200 |

| Capacity(tires/h) | 40-60 | Capacity(tires/h) | 60-120 |

| Adapt Tire Size(mm) | ≤φ1200 | Adapt Tire Size(mm) | ≤φ1200 |

| Powder(kw) | 11 | Powder(kw) | 15 |

| Puling Force(T) | 15 | Puling Force(T) | 30 |

| Size(mm) | 3890*1850*3640 | Size(mm) | 2250*1650*1500 |

| Weight(T) | 2.8 | Weight(T) | 6 |

Español

Español English

English Français

Français Русский

Русский Português

Português عربي

عربي 日语

日语